Inventory list.

Today I will develop another of the tools of the energy program proposed in the article Energy Program: the inventory list. The objective is to disclose potentials that come from differences in equipment efficiency.

In this case we will make a detailed list of the machinery that consumes energy. Apart from identifying the device, manufacturer and model, we will note its characteristics.

Theoretical efficiency.

With the theoretical efficiency we can establish comparisons, determine potentials and then try to implement the energy saving projects.

It is important to record the power consumed and its theoretical efficiency though this second is sometimes difficult to find in the technical documentation. If we only have the theoretical power, at least we can rate and prioritize the saving actions. The next step is to measure the real efficiency and use this value instead of the theoretical which is a more accurate approach.

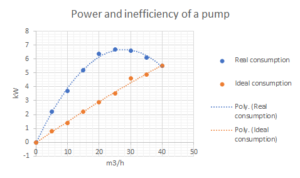

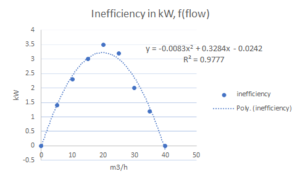

Inefficiency curve.

We can transform the work point of the equipment into inefficiency, as a measure of the excess power consumed, in kW. In the fine redesign article part 2, I explained how to do it. With the theoretical curve of the manufacturer or with a curve that we build measuring several points.

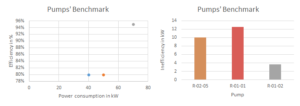

Grouping equipment for benchmark.

With the efficiencies we can establish comparisons, determine potentials and then try implement energy saving projects. We can group the teams by families and determine which is the most efficient and use this equipment as a reference.

Probably with a graph is easier to determine the differences.

Improve efficiency: fine tuning or redesign?

In addition, to know the order of magnitude of the project (redesign or adjustment) we can use the information mentioned in the post Fine adjustment or redesign, part 1 and part 2.

Inventory list: a living document.

As a conclusion, the inventory list has to be updated and revised properly and the actions resulting from the study of the list is the development of purchase procedures for equipment with minimum efficiency requirements. These procedures can be added to the manual of the energy management system that we have.