Short term metering

This is the fourth tool of the energy program that I introduced in my post: an energy program. Short term metering aims to discover potentials that come from differences in equipment efficiency. But there are other applications that I also explain in this article.

Some of these applications are:

- To study the efficiency of a device or system.

- For similar systems comparison.

- Properly sizing of industrial systems.

- To measure the results of savings projects.

To know the efficiency of a equipment or system

When we have few meters we can use portable meters and measure an equipment or a group of them to determine what is the current efficiency and compare with its maximum.

Normally, measuring only one device in a system with many is not enough because the operation parameters are interrelated. This is the reason why several machines have to be measured at the same time, all of which are intertwined. So we define a cluster with the system we want to study. And we measure the consumption of the equipment in a defined period of time.

We can use the energy detective’s tricks if we do not yet have enough counters for all consumers. These consumers have to be measured simultaneously because the process varies continuously.

Again, we will determine potentials and later try to implement projects. Our point of reference is the theoretical or the maximum consumption of the equipment, which is the area of maximum efficiency. We can also try to measure the device at various working points to determine what is its operating curve.

To know the order of magnitude of the project (redesign or adjustment) we can use the information mentioned in the post Fine tuning or redesign, part 1 and part 2.

Short term metering for benchmarking

We can also use the temporal measurement to compare between several systems that are similar. For example, for the production of cooling, heating, compressed air, etc.

In this case we make the different cluster with the involved devices and measure them.

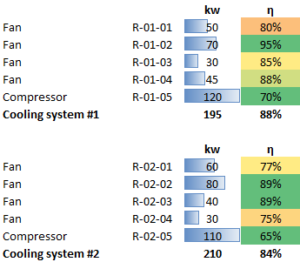

With the data we can compare the systems. We can establish a global efficiency of the system as the sum of all the efficiencies of the equipment weighted by the power of each device.

The result could be the following table:

Short term metering for correctly sizing

Another application of the temporary measuring is to know if our equipment has been well sized. If so it will work in the upper area of the efficiency curve (green area of the below picture). If on the contrary has been over-sized it will work in the inefficient zone (pink area in the below picture).

In the below video I show an example of a system (centrifugal pump, air compressor, etc.) with a single equipment that works in an inefficient area. after checking the measurements, the device is replaced by two smaller ones that work in their efficient zones. This results in a higher overall efficiency and energy savings.

To know the order of magnitude of the project (redesign or adjustment) we can use the information mentioned in the post Fine tuning or redesign, part 1 and part 2.

Short term metering for savings project measurement

Another use of the short term metering is to evaluate the results of an energy efficiency project. To do this, we measure a representative period of time must before and after the implementation of the savings project. We can make an average with each of the two periods and the difference will be the savings that the project gives us.

Watch out. Both periods have to be comparable. There may be variables that are not constants in both periods. For instance, weather conditions. In this case we make a mistake. To solve this problem it is best to try to understand what is the relationship between climatic conditions and energy consumption. We will try to obtain a theoretical energy, a function of the climatic conditions. This will be our reference line for verification. For a more extensive explanation, go to my article on How to properly measure savings from a project.

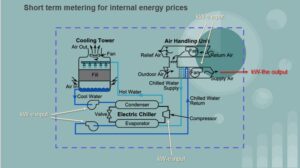

Short term metering for internal prices calculation

The last application of the temporary measure is for the calculation of the internal prices of energy. Inside a factory we could say that there are many types of secondary energies (hot water, cold water, compressed air, etc.) apart from the primary energies (electricity and gas).

It is important that we know how much each of these energies costs us. This is fundamental when we approach savings projects. Usually we measure the secondary energy before and after, but we have to monetize the saving. This is very important when prioritizing a list of savings projects. Only when we have translated the savings into money can we calculate the payback, knowing the cost of the investment. It may be a rough or an accurate estimate. More information about the estimates in my article about the process of generating savings projects.

So, what we do is to measure the primary energy consumption of the devices that produce the secondary energy in a given period of time. In parallel, we check the flow of the secondary energy generated.

As we know the price of the primary energies that we buy, we can calculate the price of secondary energies. For example, we can use the following formula:

€/ cbm = Σ (kwh-e) x €/kwh-e, where kwh-e and cbm are measured.

Below a picture of a temporary metering of industrial systems. In this example, we measure the electrical consumption of compressed air production and the output flow of compressed air, our secondary energy.